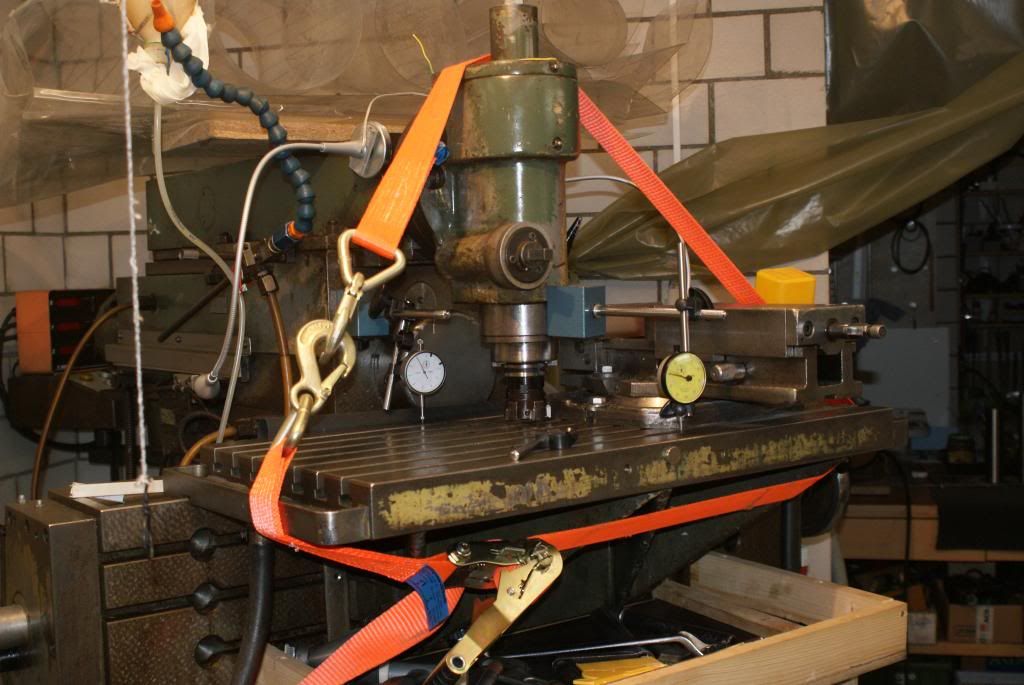

i have this well used mill, that seems to be a deckel clone (i never found out who made it), so i thought id post here. when i suspend the table on the strap and raise it with the handwheel, the rear indicator moves by 0.2 mm before the other one starts moving. so the table sags quite a bit.

![]()

i hoped to be able to adjust this with the gibbs, but there is only one gib on the side of the one of the ways:

![]()

![]()

so, is there any way of adjusting the sag? probably not. why is there only one gib? is the other side running loose? interestingly the scraping/flaking on the front of the ways looks pretty unsused. so it is strange there should be so much wear on the mating surfaces. how would i fix the sag, if i was to disassemble the mill? put some turcite on the "back plates" bolted from the back?

and yes, what are the two big, black bolt/nuts?

i hoped to be able to adjust this with the gibbs, but there is only one gib on the side of the one of the ways:

so, is there any way of adjusting the sag? probably not. why is there only one gib? is the other side running loose? interestingly the scraping/flaking on the front of the ways looks pretty unsused. so it is strange there should be so much wear on the mating surfaces. how would i fix the sag, if i was to disassemble the mill? put some turcite on the "back plates" bolted from the back?

and yes, what are the two big, black bolt/nuts?