Hi everyone, got bit of an issue I'm trying to resolve with the vertical head on my little RIKEN milling machine.

I dissasembled yesterday, and have satisfied myself the leak emintates from inbetween the O.D. of the quill & head casting, rather than the quill & tapered spindle body (as I initially thought).

The design being closed based on the deckel fp1 (Mk2), and possibly closest to the "Alexander master toolmaker", wondering if anyone familiar with the designs mentioned might be able to shed some light on:

#roughly what measures were built in to prevent leakage i.e seals etc, (because I'm seeing a distinct lack of any, other than the close fit of quill which is possibly fine when new)

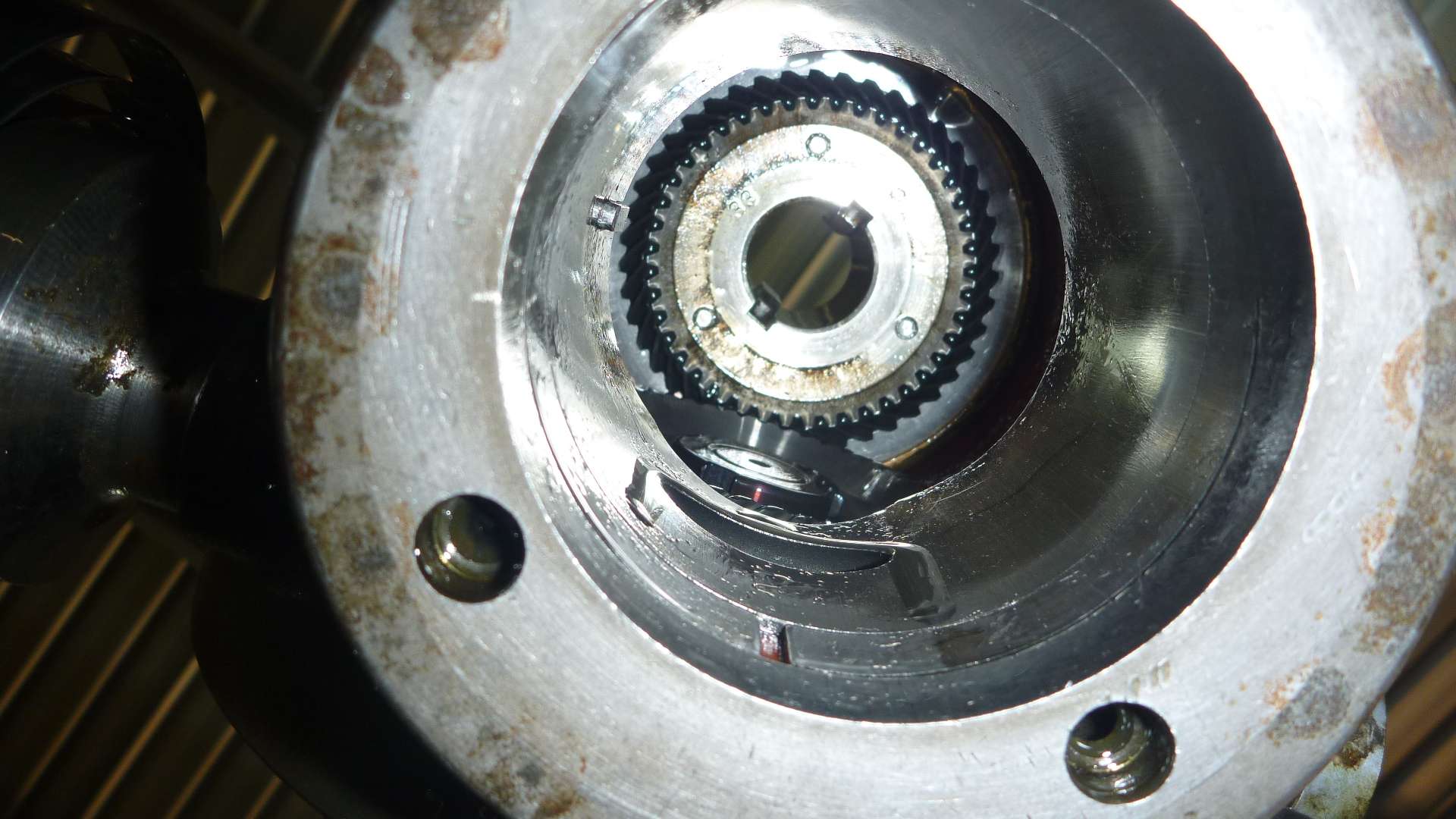

#anyone know if the split clamping ring for the quill in the bore of the head can be removed? (see picture) or would it have been pressed/heated in?

I see this as being the most definite remedy - remove & machine a recess for a lip seal?

# what purpose does the bakelite ring/washer serve? it sits pretty freely atop the spindle, on the lock nuts responsible for thrust bearing preset.

-Would be interested to hear any other imput as to how to go about fixing this-

-also took the spindle apart and adjusted bearings, replaced the lubricating felts etc (pic is the before shot - hence why they look abit anemic and pretty scruffy-

![]()

![]()

![]()

![]()

![]()

![]()

Anyway can provide more detail later, but just thought I'd get the topic up quick - to get some diagnostics people on the job

THANKS

I dissasembled yesterday, and have satisfied myself the leak emintates from inbetween the O.D. of the quill & head casting, rather than the quill & tapered spindle body (as I initially thought).

The design being closed based on the deckel fp1 (Mk2), and possibly closest to the "Alexander master toolmaker", wondering if anyone familiar with the designs mentioned might be able to shed some light on:

#roughly what measures were built in to prevent leakage i.e seals etc, (because I'm seeing a distinct lack of any, other than the close fit of quill which is possibly fine when new)

#anyone know if the split clamping ring for the quill in the bore of the head can be removed? (see picture) or would it have been pressed/heated in?

I see this as being the most definite remedy - remove & machine a recess for a lip seal?

# what purpose does the bakelite ring/washer serve? it sits pretty freely atop the spindle, on the lock nuts responsible for thrust bearing preset.

-Would be interested to hear any other imput as to how to go about fixing this-

-also took the spindle apart and adjusted bearings, replaced the lubricating felts etc (pic is the before shot - hence why they look abit anemic and pretty scruffy-

Anyway can provide more detail later, but just thought I'd get the topic up quick - to get some diagnostics people on the job

THANKS