I am in the process of restoring my 1952 FP-1 and have discovered that the quill on the vertical head is marked in millimeters while the rest of the machine is emperical. Doubting that Deckel would have originally supplied the machine like this, I now have no idea what vintage the vertical head is and am thus wondering what its bearing configuration is.

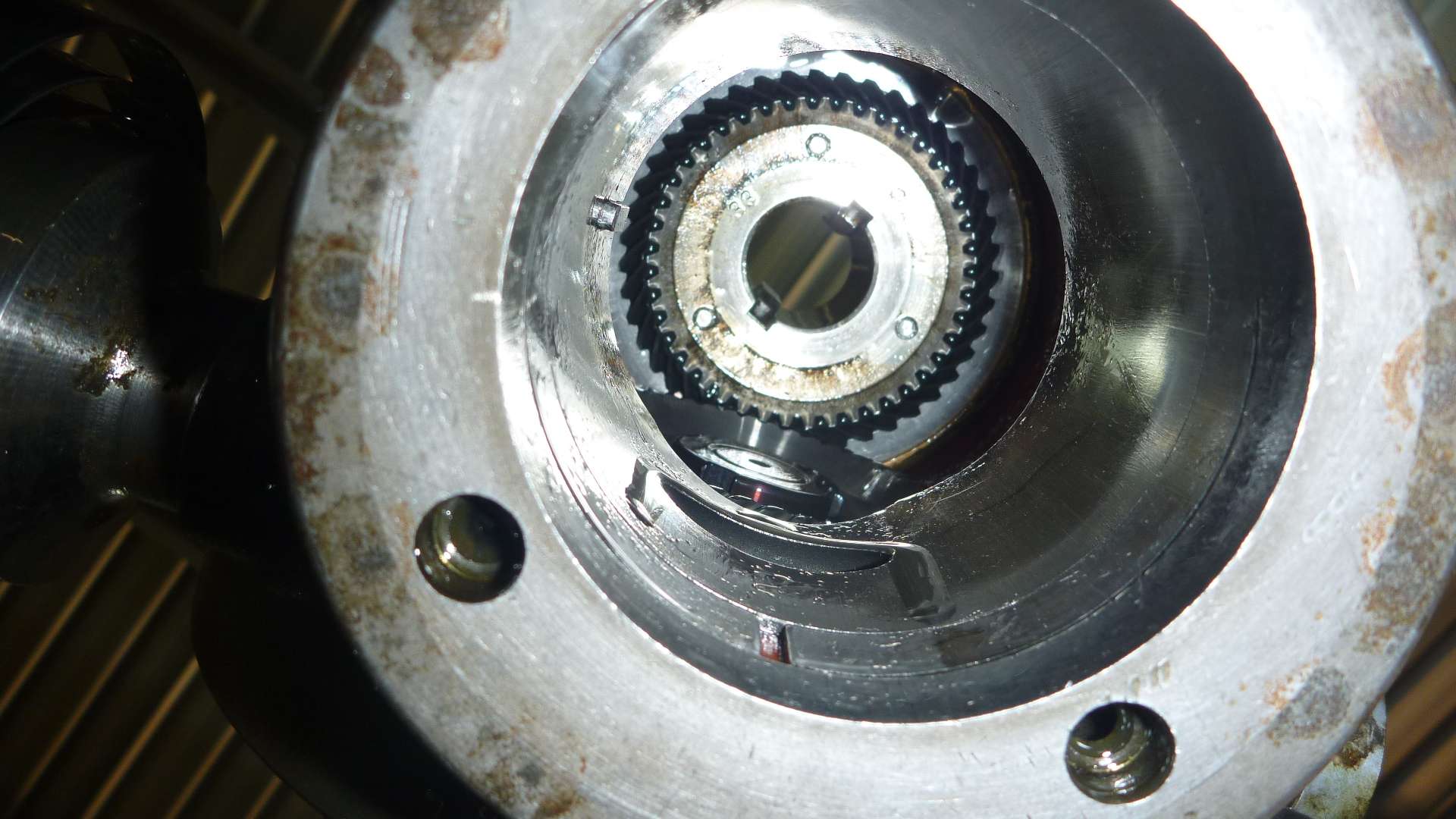

I have removed the quill from the cast housing but have not removed the spindle from the quill. The 2 uppers are ball bearings but I don't know the configuration of the lower bearings. (Needle vs bushing etc.) I hesitate to remove the spindle from the quill because it appears to be original. The locking ring on the spanner nut is unadultrated and the spindle feels very smooth and has no noticable play.

I'm wondering if someone in the past has scavanged parts to assemble this vertical head because the gear shaft, (that raises and lowers the spindle,) fits so tightly in the housing that you have to tap it into place. It can be rotated with a wrench, but not by your bear hand, and certainly not by the return spring. This is an easy fix in the lathe with some gentle emory cloth, but it does make you wonder about this machine's history over the past 60 years!

My inclination is to leave the spindle alone but wanted to ask for advice.

Thanks for any input,

Gaylan

I have removed the quill from the cast housing but have not removed the spindle from the quill. The 2 uppers are ball bearings but I don't know the configuration of the lower bearings. (Needle vs bushing etc.) I hesitate to remove the spindle from the quill because it appears to be original. The locking ring on the spanner nut is unadultrated and the spindle feels very smooth and has no noticable play.

I'm wondering if someone in the past has scavanged parts to assemble this vertical head because the gear shaft, (that raises and lowers the spindle,) fits so tightly in the housing that you have to tap it into place. It can be rotated with a wrench, but not by your bear hand, and certainly not by the return spring. This is an easy fix in the lathe with some gentle emory cloth, but it does make you wonder about this machine's history over the past 60 years!

My inclination is to leave the spindle alone but wanted to ask for advice.

Thanks for any input,

Gaylan