Well it is not a mill, but it is built in Italy. I posted awhile back some photos of running my FP4NC to cut grip grooves into a set of connecting rods that

were then going to be babbited.

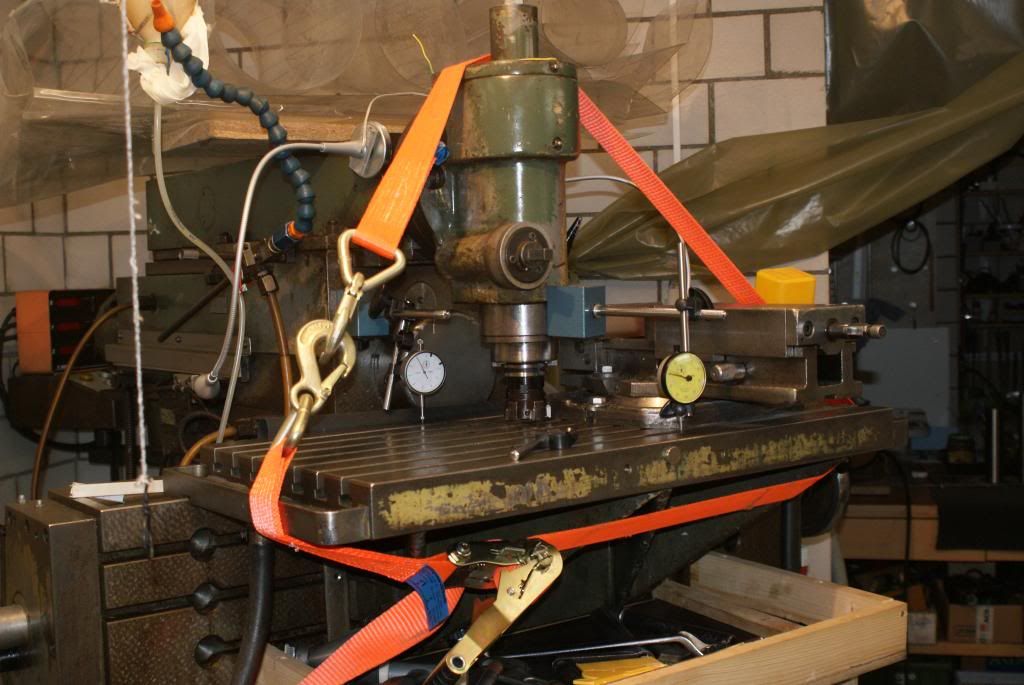

Well i thought some of you might be interested in seeing the machine that i use to finish the connecting rods....It is a pretty simple design.

Has a belt driven spindle with 4 speeds...two belt steps and a high/lo motor...

Spindle has a 40 taper but uses a non standard draw bar...the holders having a 12x1.75 male thread at the end of the taper.

![]()

I have several Berco machines. A line boring machine for doing main housing and cam bores, the rod machine and a surfacing/cylinder boring machine

Here is a rear quarter view of the machine.

The spindle usually mounts a straight bar that is cross drilled at the end for accepting a tool bit. There are a number of different sized bars to allow boring different sized

holes..either at the big end or the wrist pin end of the rod.

The vertical casting has a screw that moves a mounting plate up and down on the face of the casting. The plate is fitted with bores and clamps to secure flanged expanding mandrels.

The vertical casting is mounted on dovetail ways at right angle to the spindle...much the same as a lathe cross slide.

The base below the cross ways has another set of ways that allow the vertical casting to move parallel with the spindle...like the carriage of a lathe.

The handwheel moves the slide and is provided with power feed having two rates...coarse and fine.

![]()

![]()

![]()

More to follow....

Cheers Ross